Release time:2022-02-28

During the injection molding process, the dents of the plastic shell are shrinkage dents generated after the plastic is cooled and hardened, which mainly appear in the thick wall of the plastic shell, ribs, shell, nut insert back, etc.

1、 Equipment:

(1) Insufficient feeding

The screw or plunger is seriously worn, and the molten material leaks during the injection and pressure maintaining process, which reduces the mold filling pressure and the amount of molten material, resulting in insufficient molten material.

(2) Nozzle hole too large or too small

If it is too small, it is easy to block the sprue; if it is too large, the injection force is small, and it is difficult to fill the mold.

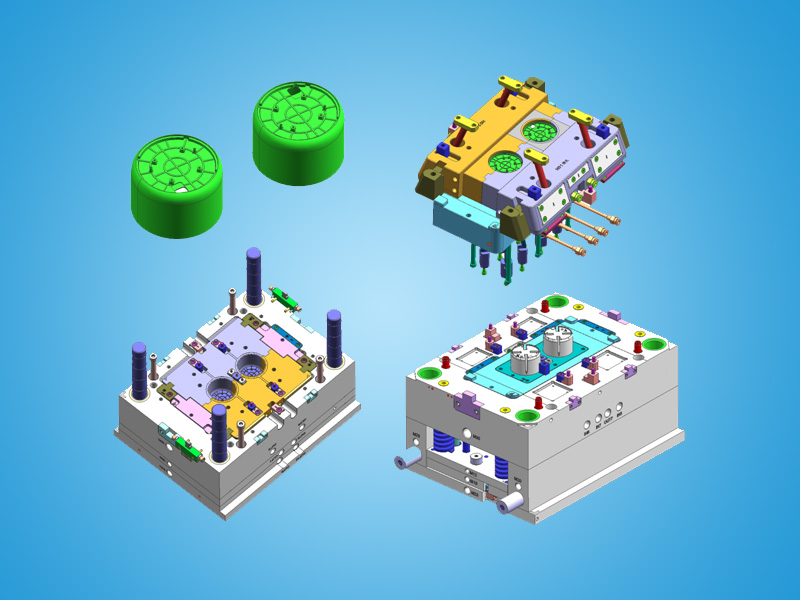

2、 Mold:

(1) The gate is too small or the runner is too narrow or shallow, the runner efficiency is low, the resistance is large, and the molten material is cooled too early.

The gate cannot be too large, otherwise the shear rate will be lost, the material viscosity is high, and the plastic shell will not be full. The gate should be opened on the thick wall of the plastic shell. By setting up a cold charging well with sufficient capacity in the flow channel, the cold charging can be excluded from entering the mold cavity, so that the mold filling can continue.

The gate length of point gate and needle gate must be controlled below 1mm, otherwise the plastic will solidify rapidly in the gate, affecting the pressure transmission; If necessary, increase the number of point gates or gate positions to meet the actual needs; When the flow passage is long and thick, exhaust grooves should be set at the edge of the flow passage to reduce the blocking effect of air on the flow of materials.

(2) Multi gate mold should adjust the filling speed of each gate, and it is best to set up gates symmetrically.

(3) The key parts of the mold should be effectively set with cooling channels to ensure that the cooling of the mold has a good effect on removing or reducing shrinkage cavities.

(4) The whole mold should be free of burrs, have reliable mold closing tightness, and can withstand the filling of high-pressure, high-speed, low viscosity molten materials.

3、 Technical aspects:

(1) Increase the injection pressure, maintain the pressure and prolong the injection time.

For plastic with high fluidity, high pressure will cause flash and collapse, so the material temperature should be appropriately reduced, and the temperature of the front of the barrel and the nozzle should be reduced, so that the volume change of molten material entering the cavity is reduced, and it is easy to cold solidify; For high viscosity plastics, the barrel temperature should be increased to make it easier to fill the mold. When the gate area shrinks, the pressure holding time should be extended.

(2) Increasing the injection speed can easily fill the parts and remove most of the shrinkage.

(3) The thin-walled plastic shell should increase the mold temperature to ensure the smooth flow of materials; The thick wall plastic shell should reduce the mold temperature to accelerate the curing and shaping of the skin.

(4) The cooling residence time of the plastic shell in the mold is prolonged, the production cycle is kept uniform, the back pressure is increased, and a certain buffer pad is reserved at the front end of the screw, which is conducive to reducing the shrinkage phenomenon.

(5) The low precision plastic shell should be taken out of the mold as soon as possible and cooled slowly in air or hot water, so that the shrinkage depression can become smooth without affecting the use.

4、 Raw materials:

The raw material is too soft and easy to flow. The effective way is to add nucleating agent to the plastic to accelerate crystallization.

5、 Plastic shell design:

The design of plastic shell should make the wall thickness uniform and try to avoid the change of wall thickness. For plastics with large shrinkage such as polypropylene, when the thickness changes by more than 50%, it is best to replace the thickened part with ribs.